What are the advantages of flat wire motors over round wire motors? Do flat wire motors have an absolute advantage over round wire motors?

The answer is, not necessarily!

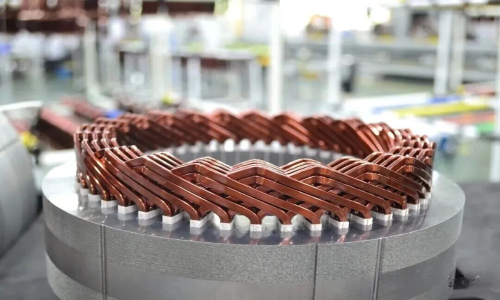

As the name suggests, the biggest difference between flat wire motors and round wire motors is that they use a single flat wire instead of multiple strands of round wire. Furthermore, they utilize a unique winding and forming process, significantly improving their slot fill rate.

How much of an improvement? The pure copper slot fill rate (excluding the copper wire insulation thickness) of flat wire motors is 20% higher than that of round wire motors! While traditional round wire distributed motors have a maximum pure copper fill rate of 48%, flat wire hairpin motors can achieve 70%!

So, can this advantage of flat wire motors actually translate into improved motor efficiency, thereby reducing energy consumption or, in other words, fuel consumption (for hybrid vehicles)?

Not necessarily!

If the CLTC (or WLTC) operating conditions used to evaluate the efficiency of new energy vehicle motors are concentrated in the low-speed, low-torque range, then the slot fill factor advantage of flat-wire motors can translate into improved motor efficiency. This is because copper losses account for the majority of motor losses in this low-speed, low-torque range. Increasing the copper fill factor of flat-wire motors significantly reduces these losses. This clearly demonstrates the advantage of flat-wire motors. In this range, flat-wire motors can be 1-2 percentage points more efficient than round-wire motors. However, if the CLTC or WLTC operating conditions encompass the low-torque and full-speed range, the copper fill factor advantage of flat-wire motors may not necessarily translate into improved energy consumption or efficiency. Why? Because of the AC losses of flat-wire motors at high speeds and high frequencies. These increased AC losses significantly increase overall copper losses, especially above base speed, where AC losses continue to increase with speed. Round-wire motors do not experience this issue. Therefore, in this scenario, flat-wire motors may not necessarily have an efficiency advantage when averaged under CLTC conditions.

If flat wire motors don’t have an absolute advantage, why promote them? Because of heat dissipation! Besides their copper fill rate advantage, flat wire motors offer an even greater advantage: better heat dissipation than round wire motors. The temperature difference between the innermost and outermost windings of a round wire motor can reach 30-40°C across the stator diameter, while for a flat wire motor, it’s only 15-20°C! The heat dissipation advantage of flat wire motors is significant, and if combined with high-efficiency oil cooling, the cooling effect is further enhanced. Oil-cooled flat wire motors offer 20% higher current-torque density than round wire motors of the same specifications (when compared at the same maximum motor temperature). This advantage goes beyond efficiency improvements, resulting in both cost and performance improvements! Today’s new energy vehicle motors prioritize cost (while balancing efficiency). Therefore, flat wire motors with oil cooling are the optimal combination for new energy vehicles! In summary, flat wire motors offer two key advantages over round wire motors: increased copper fill rate and improved heat dissipation. Under certain conditions, these two advantages can directly translate into reduced vehicle energy consumption and improved cost performance. Furthermore, flat wire motors are best paired with oil cooling.